plug flow reactor example problem

Example 5 Percent Approach to Equilibrium For a reversible reaction with rate equation r L A 1 AVl6 the size function kVV of a plug flow reactor will be found in terms of percent approach to equilibrium. This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above.

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

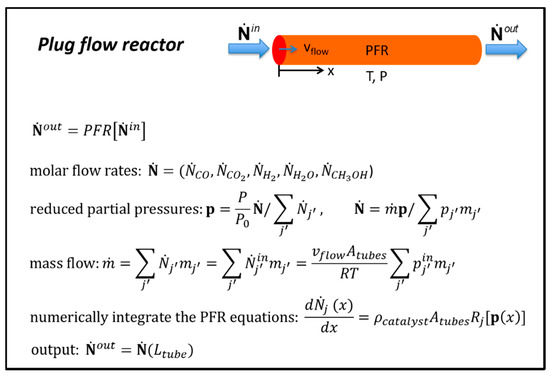

One example is in the design of chemical reactors.

. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C. Pg694 This is the equation for a plug flow reactor. Normal butane C 4 H 10 is to be isomerized to isobutane in a plug-flow reactor.

The two feed streams to the reactor mix to form a single fee d stream that is equal molar in A. The plug flow reactors describe above may be described as closed in that they are enclosed in a pipe-like geometry. A catalytic process is used for the synthesis of ammonia.

Formation rate of R is empirically correlated by the equation B A A B R C C C C r 1 05 1 rR in molLh CA and CB in molL The plug flow reactor is fed with a flow rate of 200 kmol A h and the feeding is 50 A and 50 B. Given that the system is gas phase and isothermal determine the reactor volume when X 08 X e. Is to be carried out in a flow reactor.

Determine X e for a PFR with no pressure drop P P 0. The same example problem has been worked in Aspen and Matlab. Plug flow reactor example problem Saturday June 4 2022 Edit In electronics a wafer also called a slice or substrate is a thin slice of semiconductor such as a crystalline silicon c-Si used for the fabrication of integrated circuits and in photovoltaics to manufacture solar cellsThe wafer serves as the substrate for microelectronic devices built in and upon the wafer.

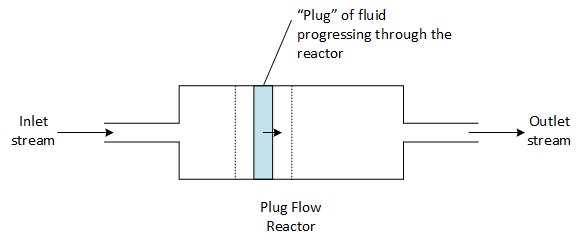

The plug flow reactor model is a model used to describe chemical reactions in continuous flowing systems of cylindrical geometry. Here polymerization and conversion reactions are performed in noncatalytic mode. Determine the reactor volume V necessary to reduce the exiting concentra- tion to 10 of the entering concentration ie CA 01Cao when the volumet- ric flow rate 2 is 10 dmmin ie litersmin and the specific reaction rate k.

K C 100 dm 3. The volumetric flow rate of the feed is 50 Lmin. The feed enters at 330 K.

The elementary liquid-phase irreversible reaction. The PFR model is used to predict the behavior of chemical reactors of such design so that key reactor variables such as the dimensions of the reactor can be estimated. Two reactors are available an 800 dm 3 PFR that can only be operated at 300 K and a 200 dm 3 CSTR that can be operated at 350 K.

The polymerization of ethylene and the conversion of naphtha to ethylene are examples. ASPEN PLUS Example Problems. Y A 02 y B 05 y C 03 C is an inert.

A 2B 2D r A -25C A 05 C B mol L-1 min-1. C A0 02 moldm 3. Fluid going through a PFR may be modeled as flowing through the.

The plug flow model has many practical applications. In plug flow the velocity of the fluid is assumed to be constant across any cross-section of the pipe perpendicular to the axis of the pipe. Another sort of plug flow reactor could be described as open.

A completed case has been pre-built and is located in the file PlugFlowExhsc in the HartsookHysysSAMP403 directory though I recommend you work. It can be derived directly from the rate equations with the aid of. A shower curtain the walls of a bathtub or a canyon wall seep all.

This elementary reversible reaction is to be carried out adiabatically in the liquid phase under high pressure using a liquid catalyst which gives a specific reaction rate of 311 h-1 at 360 K. Essentially no back mixing is assumed. The reaction takes place at 3 atm and 150C.

Thoughts on Problem Solving. The plug flow model assumes there is no boundary layer adjacent to the inner wall of the pipe. Derive an equation relating the reactor volume to the entering and exiting concentrations of A the rate constant k and the volumetric flow rate 0.

Gas phase reaction 4A B R S is performed in a plug flow reactor. The plug flow reactor is the second-most primary ideal reactor and is similar to the continuous stirred tank bioreactor. Develop equations to determine plug flow reactor size for 50 conversion of reactant A.

1 4 Continuous Flow Reactors Mole Balances In Chemical Reaction Engineering Informit

Sizing A Plug Flow Reactor Pfr Youtube

Plug Flow Reactor Vapourtec Ltd

Plug Flow Reactor Pfr Mass Balance And Reaction Speed

Introduction To Energy Balances For Plug Flow Reactors Youtube

Plug Flow Reactor Overview Youtube

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

Mole Balance On A Plug Flow Reactor Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Plug Flow Reactor An Overview Sciencedirect Topics

Isothermal Plug Flow Reactor Part 1 Youtube

Matlab In Chemical Engineering At Cmu

Thoughts On Problem Solving Pfr Cstr Example

Elements Of Chemical Reaction Engineering

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect